So, what in the world is a Wall'er-In?

A hammer-in is a gathering of blacksmiths and/or bladesmiths where knowledge is shared. A Wall'er-In is a once-a-year hammer-in at Guinea Hog Forge where we wallow in a plethora of art forms in a beautiful setting with an amazing group of demonstrators and spectators.

2025 Demonstrators from left to right - Dan Dye, Lucas House, Jacob King, Lydia McGhee, E. Scott McGhee, Peggy & Ralph McGhee, Candace Martens, Eric Steinhauer, Brian Martens, Ethan Winskey, Bruce Steinhauer, and Zach Tarbell (photo by Chris Morgan).

Chris Morgan snapped more amazing tin-type photos than I can post here.

Silversmith Dan Dye worked tirelessly for 2 days wowing the crowd with his skills.

Shop Space's Lucas House expertly forged a huge intricate riveted door pull.

VIB instructor Ethan Winskey entertained the crowd while pounding out an impressive War Hammer.

Jacob King of NCABANA had a blast educating attendees while forging colonial lighting items.

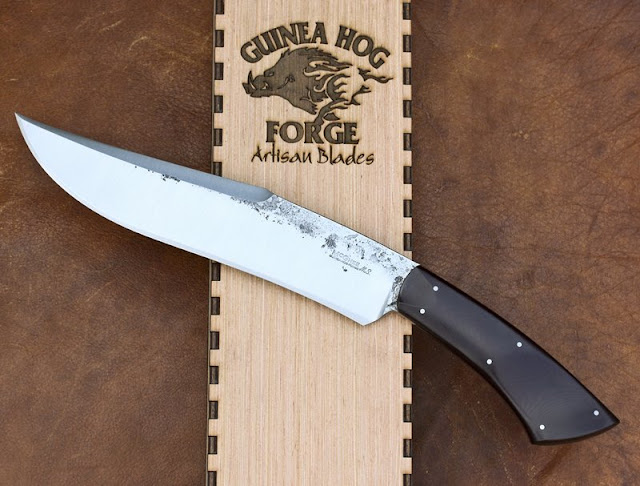

E. Scott McGhee, Zach Tarbell, and Candace Martens tag-teamed the making of a gorgeous Damascus Carving Set. On Saturday, Zach forged the 4-Way Twisted Pattern-Welded Steel, Scott forged the knife, and Candy forged the fork. Then on Sunday, they all worked together to sand, mark, etch, handle and finish the set. Photo by Jocelyn Frasier.

To the delight of attendees, Brian Martens crafted a hand-tooled copper medallion for the carving set's leather wrap live on site.

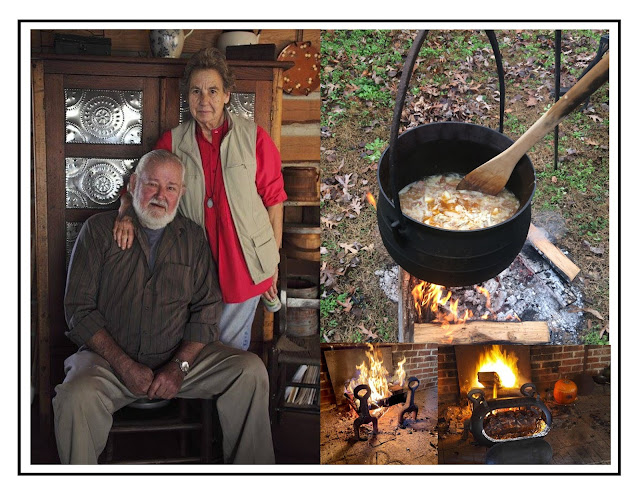

On Saturday, Bruce and Eric Steinhauer slow roasted the best pork BBQ ever on their hand-crafted rotisserie.

Peggy & Ralph McGhee (Scott's parents) cooked over the fire all weekend to make sure nobody went hungry.

On Friday, before the event began, three bladesmiths passed their Journeyman Performance Test. Congrats to Ethan Winskey, Sam Daugherty, and Zach Tarbell on this amazing accomplishment.

On Friday, before the event began, three bladesmiths passed their Journeyman Performance Test. Congrats to Ethan Winskey, Sam Daugherty, and Zach Tarbell on this amazing accomplishment.The event concluded with an auction to fund the Candace & Brian Martens GHF Scholarship Fund. The fund was established at last year's event to help those of limited means take no-cost (or low cost) classes at Guinea Hog Forge. If interested, please email guineahogforge@gmail.com for an application.

Thank you to all who came and helped support the cause. The GHF Wall'er-In is an Invitation Only Event with limited capacity. If you are interested in attending the 2026 event, please email guineahogforge@gmail.com to get on the notification list.

Next year's event is already in the works!

.jpg)